Purpose

Design a device to improve personal water transportation in aid and development situations, such as refugee camps.

Results

Full sized, functional water roller prototype.

We all need water to live. For many, getting it is a struggle, often times in circumstances where they are already fighting to survive, such as refugee camps or other aid environments. Even in situations where water is available, it may need to be transported over long distances, something that brings not only a substantial physical challenge, but also a high risk of contamination during transport and storage. The goal of this project was to design a device that could address many of these water transportation issues.

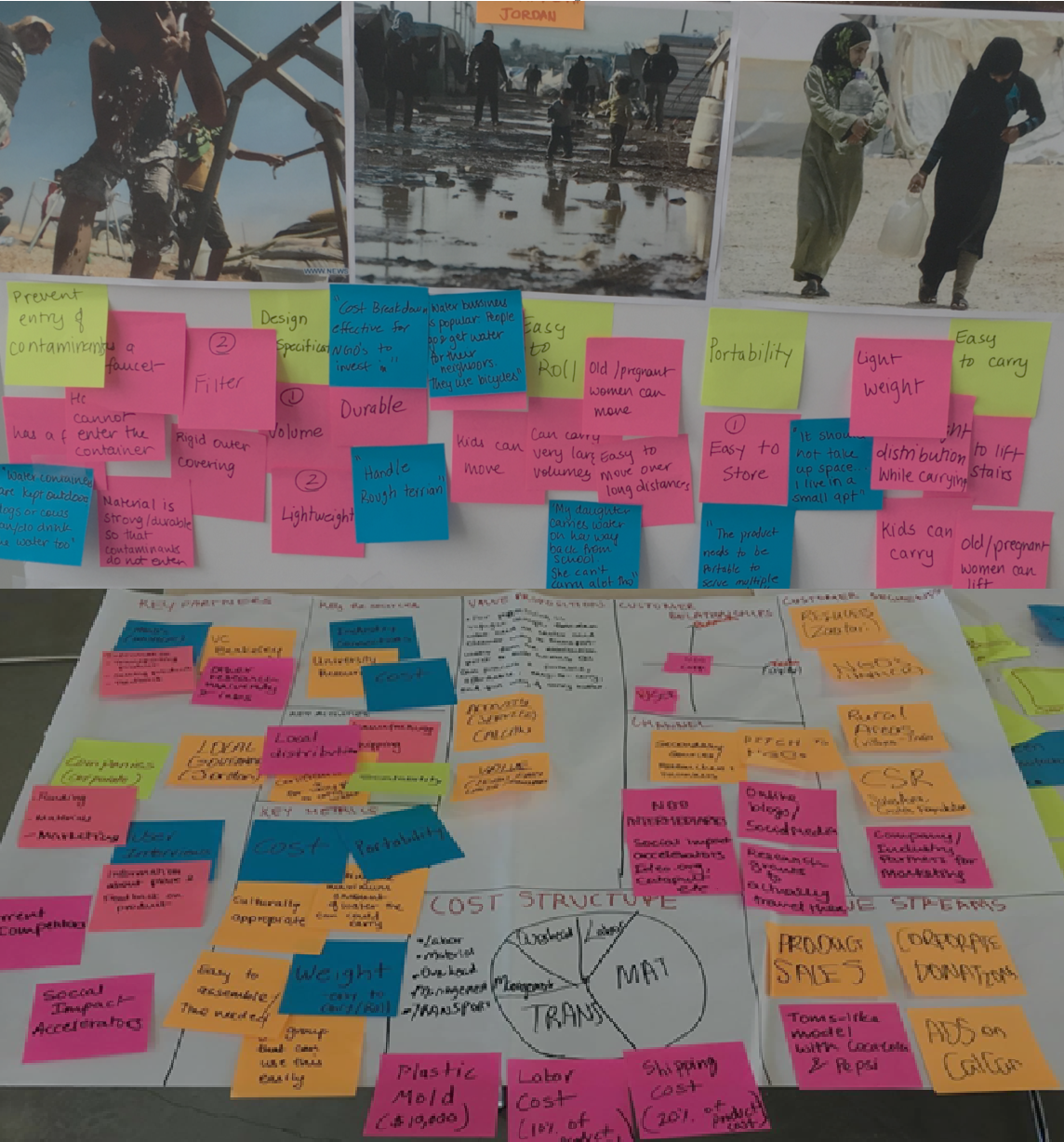

Throughout the entire process, great effort was made to ensure the design process was strongly informed by those with experience and expertise in the target environments. Needs assessments were developed based on interviews with inhabitants of refugee camps and experts with various aid and development backgrounds.

The processes yielded several defined needs, including:

- Ease of usage

- Reliability

- Resistance to contamination

- Low manufacturing cost

- Ease of shipping

Having established needs, next step was to set about meeting them. After a highly iterative process, concept specifications and features began to take shape. These included:

- Rolling design for ease of movement

- Separate water bladder to maintain a sealed environment during transport, allow easy removal for cleaning and storage, and replacement for damage

- Truncated cone external shell design for ease of manufacturing, structural strength, and compact stacking for shipping

In addition to these points, the separate shell design allowed for usage of recycled or non-consumption safe plastics, unlike solid roller systems, and the shell would not need to be water tight. Also, the design incorporated multiple internal bladders to limit dynamic effects of water turbulence during rolling as well as potential water loss due to damage.

With design work completed, a full size prototype was built. While all design and manufacturing features and characteristics could not be exactly replicated, the prototype served to test the rolling dynamics as well as the strength and viability of the design materials. The prototype worked successfully.